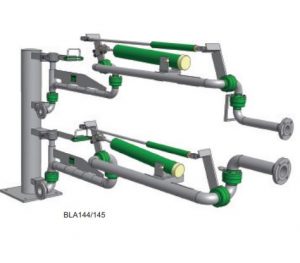

BOTTOM LOADING ARMS

Introduction

Bottom loading/unloading arms are designed to be connected on the side or on the rear of the tanker and sometimes for both.

Bottom loading arms are provided with 5x or 6x swivel joints and 1x balancing system (spring cylinder). In order to keep the connection pipe horizontal, bottom loading arms (type BLA124. BLA125, BLA144, et BLA145) are provided with a pantograph. They can equipped with a large number of accessories.

Depending on the requirements involved, the design can vary from standard solution to tailor made.

Basic characteristics

- Diameter : 2’’ (DN50), 3’’ (DN80), 4’’ (DN100) et 6’’ (DN150)

- Materials (piping) : Carbon steel, Carbon steel Low Temperature, Stainless Steel 304L, Stainless steel 316L, PTFE lined, other material on request

- Product seal : PTFE-C, PTFE virgin, FPM, NBR, UHMW-PE, other material on request

- Balancing: counterweight or spring cylinder

- Balancing : Spring cylinder

- Temperature range: -200ºC up to +300ºC

- Pressure range: maximum 63 bar

Design data may include:

- Required norm : CE Machinery Directive 2006/42/EG, PED 97/23/CE, ASME B31.3, EN13480, ATEX 94/9/CE

- Type of product, viscosity, density

- Flow rate

- Unloading by gravity

- Site and existing working conditions (loading platform height, height of inlet flange of product line, roof…)

- Connection to tanker: flange, coupler…

- Detection of stored, working position

- Heating (electric, steam, hot oil) with or without insulation

- Number of loading arms working together on the same tanker

- Combination with shut-off valves, metering sikd, weighbridge

https://kanon.nl/truck-loading-arms/